|

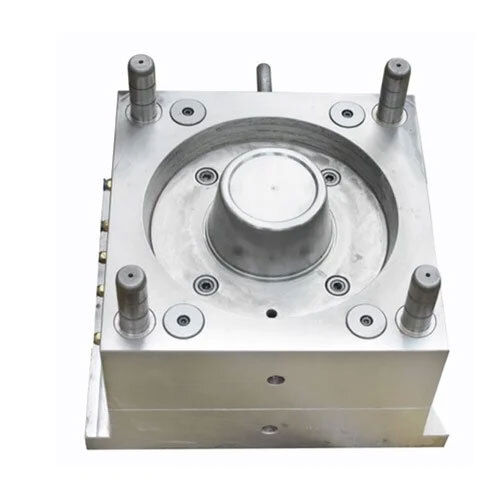

Plastic Toy Mould

Price 150000.0 INR/ Piece

Plastic Toy Mould Specification

- Molding Material

- Plastic

- Life Span

- 5-10 years

- Mold Base

- Standard

- Cavity

- Single / Multiple (as per design)

- Shaping Mode

- Injection Mould

- Usage

- Injection Moulding

- Material

- Steel

- Size

- Standard

- Tolerance

- 0.01 mm

- Product Type

- Plastic Toy Mould

- Mould Weight

- Depends on design (usually 200-500 kg)

- Color

- Silver

- Mould Life

- 500,000 to 1,000,000 shots

- Core/Cavity Material

- P20, 2738, H13, S136 (as required)

- Ejection System

- Ejector Pins / Plates

- Cooling System

- Water cooling channels integrated

- Runner System

- Hot / Cold runner optional

- Surface Finish

- Polished

- Hardness

- HRC 45-52

- Packaging Type

- Wooden Box

- Manufacturing Process

- CNC, EDM, Milling

- Design Software

- AutoCAD, UG, ProE, SolidWorks

Plastic Toy Mould Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- INDIA

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA)

- Average Load Time

- 60-120 seconds

- Supply Ability

- 10 Per Week

- Delivery Time

- 7 Days

- Sample Available

- No

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Plastic Toy Mould

Plastic toy molds are used to mass-produce plastic toys. Molten plastic is injected into the mold, cooled, and ejected, creating toy parts. Mold design, material, and precision are crucial for producing safe, durable, and appealing toys.Superior Materials and Craftsmanship

Constructed from high-grade steel alloys such as P20, 2738, H13, and S136, this mould ensures robust durability and consistent quality. Each mould undergoes precision CNC, EDM, and milling for accurate shaping and flawless fit, reflecting a commitment to exceptional craftsmanship and longevity.

Precision Engineering and Versatile Design

Utilizing design software like AutoCAD, UG, ProE, and SolidWorks, our experts deliver moulds tailored to individual client needs. With options for single or multiple cavities and standard mold bases, the design flexibility supports diverse toy manufacturing requirements, making this mould a dependable choice.

Optimized Performance and Easy Maintenance

The integrated water cooling system and polished surface finish enhance injection moulding productivity while simplifying maintenance. Ejector pins and plates guarantee efficient part removal, and the mould life of 500,000 to 1,000,000 shots ensures long-term performance and value for business operations.

FAQs of Plastic Toy Mould:

Q: How is the plastic toy mould manufactured to ensure precision and durability?

A: The mould is produced using advanced CNC, EDM, and milling processes with premium steel materials such as P20, 2738, H13, and S136. These methods guarantee precise dimensions, a polished finish, and robust durability suitable for high-volume injection moulding.Q: What are the benefits of having both hot and cold runner options in the mould?

A: Offering hot and cold runner systems provides flexibility in injection moulding. Hot runners streamline operations and reduce material waste, while cold runners offer simplicity and easier maintenance, enabling manufacturers to choose the system that best suits their needs.Q: Where is the mould most commonly used and how is it packaged for delivery?

A: This mould is primarily utilized in injection moulding factories, especially for producing plastic toys. For safety and ease of transport, each mould is securely packaged in a wooden box for delivery anywhere in India.Q: When should the mould be replaced or serviced for optimal results?

A: With a lifespan of 500,000 to 1,000,000 shots and an overall life span of 5 to 10 years, regular inspection, cleaning, and timely servicing are recommended to maintain precision and extend usability before replacement is considered.Q: What advantages does the integrated water cooling system provide in the injection moulding process?

A: The water cooling channels help regulate mould temperature during production, resulting in faster cycle times, higher product quality, and reduced risk of warping, which is crucial for achieving consistency in plastic toy manufacturing.Q: How can buyers specify their desired mould cavity and size requirements?

A: Customers can choose between single or multiple cavity designs and standard mould sizes as per their production scale. Designs can be customized using supported software such as AutoCAD, UG, ProE, and SolidWorks to align with individual project specifications.Q: What is the typical tolerance and hardness achieved with this mould, and why does it matter?

A: The mould is built to a tight tolerance of 0.01 mm and hardness between HRC 45-52. This precision and resilience ensure consistent toy shapes, fewer defects, and sustained performance throughout the moulds operational life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Injection Mould Category

Inline Water Filter Mould

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Number

Material : Steel

Color : Silver

Usage : Injection Moulding

Product Type : Inline Water Filter Mould

Dozing Pump Mould

Price 150000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other

Color : Blue

Usage : Industrial

Product Type : Dozing Pump Mould

Cooler Parts Plastic Injection Mould

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Number

Material : Other

Color : Silver

Usage : Industrial

Product Type : Cooler Parts Plastic Injection Mould

Plastic Food Container Moulds

Price 250000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other

Color : Silver

Usage : Injection Moulding

Product Type : Plastic Food Container Moulds

|

Maruti Industries

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry